Subscribe to EDOM TECH Newsletter

2022/10/19

How new sensor and LED technology enhances UV-C treatment systems?

Author: Markus Busz - Senior Product and Marketing Manager in Spectral Sensing Segment

The combination of high-performance UV-C LEDs and an advanced UV sensor ensure effective treatment of pathogens while maintaining user safety

Since the onset of the Covid-19 pandemic in 2020, interest in the use of ultraviolet (UV) light to combat contamination and infection by bacteria, viruses and spores has spiked. The science of UV treatment is well understood: it is known that light in the short-wavelength UV-C band effectively sanitizes surfaces, air and water.

UV-C does not occur naturally on earth, because UV-C light radiated by the sun cannot penetrate the atmosphere, unlike longer-wavelength UV-A and UV-B radiation. This is why living organisms such as viruses and bacteria have evolved no defenses against UV-C radiation: UV-C light interferes with their DNA and RNA, preventing them from replicating and thus rendering them ineffective as pathogens.

You can watch how quickly and effectively UV-C light treats contamination of a mobile phone – and learn much more about how the technology works. This demonstration also shows how a combination of technologies available from ams OSRAM – both UV emitters and a tri-band UV sensor – offers the promise of better implementation of UV-C treatment in future in consumer, industrial and specialist applications.

The key to controlling dosage and exposure

Given UV-C light is known to deactivate viruses, bacteria and spores, it is creating interest across many market sectors and applications. In the consumer world, devices can use UV-C light for air and floor sanitization in homes, or to treat water. In industrial settings, UV-C light in faucets treats water at the point of use, and cleans the air passing through large air-conditioning units. There is also potential for the use of UV-C light elsewhere: in hospitals to decontaminate the air and surfaces in rooms where patients are to occupy, or to sanitize the cabin of a commercial plane before the passengers board.

These and many other use cases have a good scientific basis in theory, but in practice run up against the two crucial issues in implementing UV-C treatment: dosage and exposure. And this is where technology from ams OSRAM promises a valuable new approach.

Cranking up the dial is inefficient

Today, UV-C treatment systems apply brute force to the question of dosage: the product data for an LED or other source of UV light cannot tell the user how much light it has emitted at the wavelength band of interest, so operators tend to turn the dial up to maximum and drench the contaminated object with as much UV light as possible to eliminate any risk of under-dosage.

The problem with this approach is that it consumes excessive amounts of power, which is especially undesirable in portable, battery-powered products. It also accelerates the aging of materials which are exposed to UV-C light sources.

In fact, this approach is a crude work-around, which is necessary, because no satisfactory method has previously existed for measuring the amount of UV-C light cast by an emitter. Today’s systems also lack a cost-effective, fail-safe method for preventing unsafe exposure to UV-C light, which is harmful to humans as well as to viruses and bacteria. The spectrometers or discrete analog sensing solutions used today are bulky and expensive. In addition, spectrometers require regular calibration.

This is a problem which ams OSRAM, a global leader in optical solutions, is in a perfect position to solve. The company launched its first low- and mid-power UV-C LEDs in 2020. The Oslon UV series offers a compact, robust and mercury-free alternative to the traditional mercury lamps used to produce UV light.

The series is growing – with innovation built in. A new high-power UV-C LED, which will be launched in mid-2022, will enable deeper, more powerful treatment in large-scale applications.

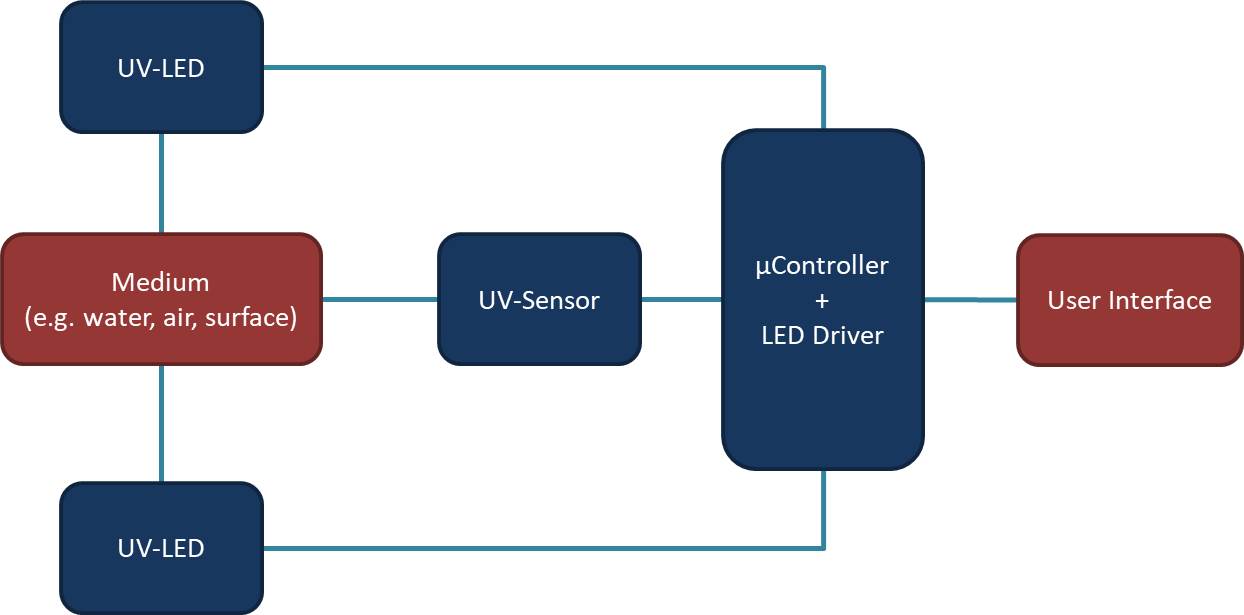

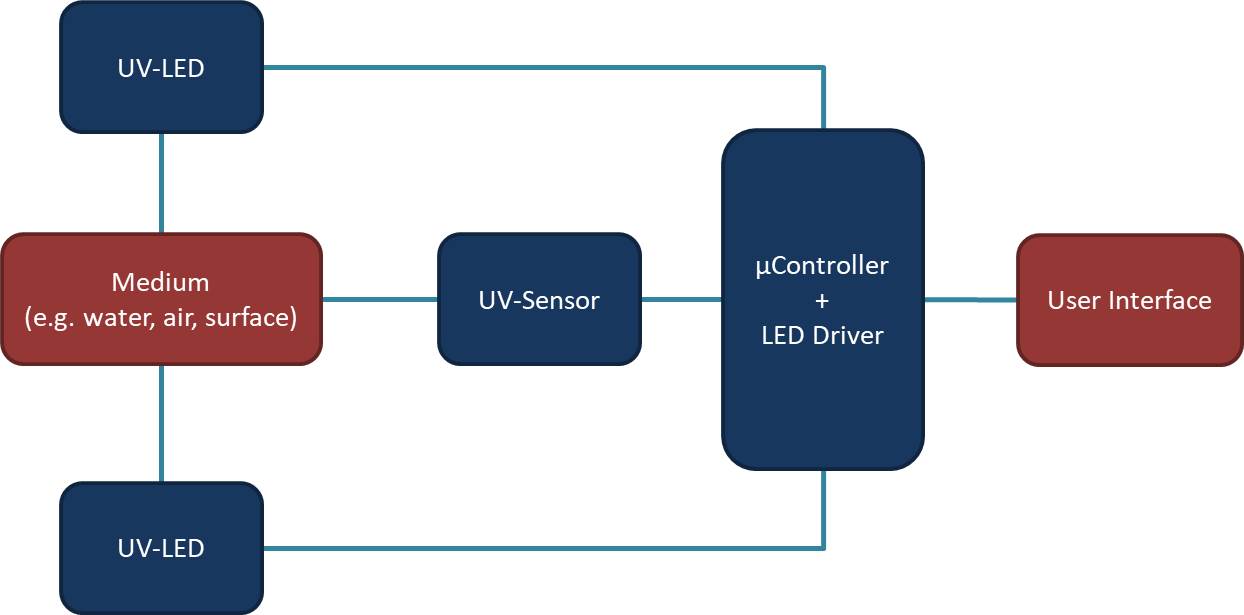

In addition to emitters, ams OSRAM manufactures optical sensors as well. By extending its capability in optical sensing from the infrared and visible light spectrums into UV light, it can enable manufacturers to build intelligent, closed-loop systems for controlling both dosage and exposure. By combining a UV sensor with Oslon UV LEDs, the dosage can be optimized precisely to achieve the treatment of contaminants required in any application.

This avoids all the drawbacks of over-exposure, such as power consumption and aging, and can also support the generation of documentation which will give the user confidence that the correct dosage has been applied, and that contamination has been eliminated. Direct sensing of UV output built into the emitter system also ensures that alerts and safety mechanisms can always be reliably activated when UV-C LEDs are on.

Smart decontamination equipment

The use of a UV sensor alongside Oslon UV LEDs could even enable the development of intelligent UV-C treatment systems, thanks to the phenomenon of bioluminescence. This is a property of organisms such as viruses and bacteria: they emit UV-A radiation when irradiated with UV-C light. A highly sensitive tri-band UV sensor (a device sensitive to UV-A, UV-B and UV-C light) can detect minute amounts of bioluminescence. This ability can be used to trigger UV-C treatment only when pathogens are detected, saving power while minimizing the risk of contamination.

Additionally, bioluminescence properties of pathogens can also be used for quality control: after the necessary dosage of UV light has been applied for the desired period of time, UV sensor can then check how many, if any, organisms are still left alive. The combination of emitter and sensor technology, a special capability of ams OSRAM, is then the basis for smarter, more efficient UV-C treatment systems.

*Article Source: ams OSRAM (A better way to decontaminate: how new sensor and LED technology enhances UV-C treatment systems)

The combination of high-performance UV-C LEDs and an advanced UV sensor ensure effective treatment of pathogens while maintaining user safety

Since the onset of the Covid-19 pandemic in 2020, interest in the use of ultraviolet (UV) light to combat contamination and infection by bacteria, viruses and spores has spiked. The science of UV treatment is well understood: it is known that light in the short-wavelength UV-C band effectively sanitizes surfaces, air and water.

UV-C does not occur naturally on earth, because UV-C light radiated by the sun cannot penetrate the atmosphere, unlike longer-wavelength UV-A and UV-B radiation. This is why living organisms such as viruses and bacteria have evolved no defenses against UV-C radiation: UV-C light interferes with their DNA and RNA, preventing them from replicating and thus rendering them ineffective as pathogens.

You can watch how quickly and effectively UV-C light treats contamination of a mobile phone – and learn much more about how the technology works. This demonstration also shows how a combination of technologies available from ams OSRAM – both UV emitters and a tri-band UV sensor – offers the promise of better implementation of UV-C treatment in future in consumer, industrial and specialist applications.

The key to controlling dosage and exposure

Given UV-C light is known to deactivate viruses, bacteria and spores, it is creating interest across many market sectors and applications. In the consumer world, devices can use UV-C light for air and floor sanitization in homes, or to treat water. In industrial settings, UV-C light in faucets treats water at the point of use, and cleans the air passing through large air-conditioning units. There is also potential for the use of UV-C light elsewhere: in hospitals to decontaminate the air and surfaces in rooms where patients are to occupy, or to sanitize the cabin of a commercial plane before the passengers board.

These and many other use cases have a good scientific basis in theory, but in practice run up against the two crucial issues in implementing UV-C treatment: dosage and exposure. And this is where technology from ams OSRAM promises a valuable new approach.

Cranking up the dial is inefficient

Today, UV-C treatment systems apply brute force to the question of dosage: the product data for an LED or other source of UV light cannot tell the user how much light it has emitted at the wavelength band of interest, so operators tend to turn the dial up to maximum and drench the contaminated object with as much UV light as possible to eliminate any risk of under-dosage.

The problem with this approach is that it consumes excessive amounts of power, which is especially undesirable in portable, battery-powered products. It also accelerates the aging of materials which are exposed to UV-C light sources.

In fact, this approach is a crude work-around, which is necessary, because no satisfactory method has previously existed for measuring the amount of UV-C light cast by an emitter. Today’s systems also lack a cost-effective, fail-safe method for preventing unsafe exposure to UV-C light, which is harmful to humans as well as to viruses and bacteria. The spectrometers or discrete analog sensing solutions used today are bulky and expensive. In addition, spectrometers require regular calibration.

ams OSRAM solution

This is a problem which ams OSRAM, a global leader in optical solutions, is in a perfect position to solve. The company launched its first low- and mid-power UV-C LEDs in 2020. The Oslon UV series offers a compact, robust and mercury-free alternative to the traditional mercury lamps used to produce UV light.

The series is growing – with innovation built in. A new high-power UV-C LED, which will be launched in mid-2022, will enable deeper, more powerful treatment in large-scale applications.

In addition to emitters, ams OSRAM manufactures optical sensors as well. By extending its capability in optical sensing from the infrared and visible light spectrums into UV light, it can enable manufacturers to build intelligent, closed-loop systems for controlling both dosage and exposure. By combining a UV sensor with Oslon UV LEDs, the dosage can be optimized precisely to achieve the treatment of contaminants required in any application.

This avoids all the drawbacks of over-exposure, such as power consumption and aging, and can also support the generation of documentation which will give the user confidence that the correct dosage has been applied, and that contamination has been eliminated. Direct sensing of UV output built into the emitter system also ensures that alerts and safety mechanisms can always be reliably activated when UV-C LEDs are on.

Smart decontamination equipment

The use of a UV sensor alongside Oslon UV LEDs could even enable the development of intelligent UV-C treatment systems, thanks to the phenomenon of bioluminescence. This is a property of organisms such as viruses and bacteria: they emit UV-A radiation when irradiated with UV-C light. A highly sensitive tri-band UV sensor (a device sensitive to UV-A, UV-B and UV-C light) can detect minute amounts of bioluminescence. This ability can be used to trigger UV-C treatment only when pathogens are detected, saving power while minimizing the risk of contamination.

Additionally, bioluminescence properties of pathogens can also be used for quality control: after the necessary dosage of UV light has been applied for the desired period of time, UV sensor can then check how many, if any, organisms are still left alive. The combination of emitter and sensor technology, a special capability of ams OSRAM, is then the basis for smarter, more efficient UV-C treatment systems.

*Article Source: ams OSRAM (A better way to decontaminate: how new sensor and LED technology enhances UV-C treatment systems)